With thousands of patents and millions of products to its credit, zinc has played a crucial supporting role in many of the major inventions of the 20th century.

When asked how zinc is used, most people would likely mention vitamins and perhaps sunscreen. Some might add galvanizing and casting to the list, but few realize just how deeply zinc and zinc-based technologies play a crucialrole in our daily lives.

Zinc is extensively involved in transportation, medicine, energy conservation, pollution control, electronics, and space exploration. Its unique properties enable it to address many current challenges and to continue making significant contributions in the future.

Zinc in Space Exploration

Zinc has no equal as a protective coating for steel. Regardless of the environment or application, the steel and zinc industries have collaborated for many years to develop complete galvanizing coatings that protect steel from corrosion. From car body panels and undercarriage components to household appliances, gas pumps, mailboxes, street fixtures, vineyard wires, and buildings, the lifespan and options available with modern zinc coatings are extensive. However, steel is not the only material that benefits from the unique properties of zinc. When scientists at NASA (National Aeronautics and Space Administration) needed a heat-resistant coating for space travel, they turned to zinc oxide. Researchers successfully developed a zinc-based coating that can withstand thermal cycling between -180°C and +180°C, as well as ultraviolet radiation equivalent to 19,000 hours of solar exposure.

This zinc oxide coating is now widely used to protect spacecraft components, which are among the most technically advanced and complex machines ever created.

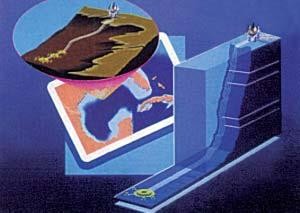

In 1997, the Cassini space probe left Earth on a seven-year journey to Saturn. Upon reaching the planet, the probe began a four-year mission, completing fifty orbits and numerous flybys of moons. Several components of the spacecraft, including its 4-meter diameter high-gain antenna system, were protected by a thermal control system based on zinc oxide. This zinc-based thermal coating was critically important, as the probe encountered extreme temperatures during its mission. As it approached 0.61 astronomical units (AU) from the Sun during flybys of Venus at low altitudes, and later, when it reached 10 AU from the Sun while orbiting Saturn, it faced intense heat that required such protective measures.

Several coatings were evaluated for the project, but the zinc oxide formulation best met the mission’s requirements, including the ability to resist extreme heat and withstand exposure to ultraviolet radiation.

Zinc oxide is used in a wide range of industries and applications, including paint production, rubber manufacturing, cosmetics, pharmaceuticals, floor coatings, plastics, fabric printing, soap making, battery storage, textiles, electrical equipment, and more.

Zinc in marine projects

As offshore oil production moves to greater depths, conventional production platforms become progressively more expensive. The mass required for steel structures increases disproportionately with water depth.

To overcome this issue, an alternative approach for ocean floor resource extraction and remote operation control has been implemented.

A series of electrical and hydraulic lines are used to connect remote resources to infrastructure located in shallow waters near the coast. Until recently, central lines were made from high-pressure plastic hoses, which were poorly stabilized over long distances, or from expensive metal alloys.

An American company, Southwestern Pipe Inc., in collaboration with the International Lead Zinc Research Organization (ILZRO) and Shell, developed a steel core coated with a flexible zinc metal layer. The flexible zinc coating, with a thickness of 750 microns (while standard zinc coatings typically range from 8 to 40 microns), provides an underwater lifespan of 30 to 40 years.

Today, the newly protected zinc-coated core is marketed under the name SEA CAT. SEA CAT is currently used in 75% of deep-water projects in the Gulf of Mexico, with over 11 million feet (3.4 million meters) of pipeline in service.

SEA CAT also plays a vital role in the world’s largest underwater development project, the NA KIKA Shell/BPAMOCO project.

This remarkable engineering achievement encompasses five underwater developments, all integrated into a permanent floating production center.

These wells are situated at depths ranging from 5,800 to 7,000 feet (1,800 to 2,100 meters), and upon completion, more than 1,000 miles (1,600 kilometers) of zinc-coated pipeline will be required.

Zinc Fireworks

Despite its many primary uses, zinc is sometimes used solely for recreational purposes. Have you ever wondered how objects glow in the dark?

All glow-in-the-dark products contain phosphorus, a substance that emits visible light after being energized.

To create an object that glows in the dark, you need phosphorus that has been energized by ordinary light and has very long-lasting stability.

Zinc sulfide has these properties and is used to create glow-in-the-dark items, such as luminous watches and glow-in-the-dark toys.

The glowing properties of zinc have made it a key material in X-rays, television screens, fluorescent lights, and LED light emissions.

In fireworks, zinc dust is commonly used to generate light and create sparkling sparks. Zinc metal pieces are heated until they glow brightly or burn at sufficiently high temperatures.

Various chemicals can be added to create glowing colors, but it is zinc that produces the sparks.

روی در فناوری روز

In today’s world, zinc casting is found everywhere, from lighting fixtures and faucets to door handles and automotive parts.

Radios, fax machines, computers, and printers are among them, but few of our modern technologies rely on zinc casting for their components.

Recently developed casting methods are fueling the race to miniaturize next-generation devices such as mobile phones and laptops. As technology is packed into ever tighter spaces, the need to dissipate heat from sensitive electronic components becomes increasingly critical.

Researchers have converted zinc alloys into small heat sinks required for cooling these devices. Zinc oxide varistors, commonly known as surge protectors, are widely used in electrical systems for circuit protection. Their primary function is to allow short-term overload currents to pass through safely.

The most important of these are varistors, which are used in high-voltage power transmission lines to protect against lightning strikes and transient power surges. They are also used in low-voltage applications to protect sensitive components such as transistors and integrated circuits.

Zinc plays a crucial role in the production of varistors. The internal component of the device is almost entirely made from zinc oxide, while the outer layer or coating is usually composed of a ceramic material or rubber mold. To manufacture the internal zinc oxide blocks, zinc oxide is mixed with other metal oxides and a binder. This powder mixture is then placed under high pressure and shaped into a disk, which is baked in a furnace for several hours. The zinc oxide particles fuse together to form a solid block. After a conductive coating is applied to the disk, multiple disks are stacked together and sealed within a shell. The size of the varistor depends on the voltage of the circuit being protected. Zinc oxide in this ceramic form exhibits a unique electrical property: at designed voltages, the block acts as a resistor, while under surge conditions, it functions as a conductor.

Zinc is also a crucial material in the design of new high-performance batteries.

Currently, researchers are developing and commercializing zinc-air batteries that are capable of powering mobile phones, hearing aids, and laptops, offering a significantly longer lifespan compared to traditional chemical batteries.

Currently, efforts are underway to scale up this technology, along with other zinc-based technologies, to make them suitable for powering cars and even homes.

For example, the truck’s engine idle mode, used to heat or cool the sleeper cabin when the truck is parked, could soon be replaced by zinc-air fuel cells, offering a clean and efficient auxiliary power source for the truck’s air conditioning system.

Currently, truck drivers in the U.S. spend up to $4,000 annually per truck idling to run auxiliary engine systems.

Other applications of zinc-air fuel cells, known for being exceptionally clean and quiet, include forklifts, lawnmowers, scooters, delivery vehicles, backup generators for the telecommunications industry, auxiliary power for boats, trucks, RVs, golf carts, and industrial cleaning equipment.

Zinc in Prestigious Awards

Every year, the US National Academy of Recording Arts & Sciences honors success in recorded music by presenting the Grammy Award.

The Grammy Award is bestowed annually by artists and technical experts in recognition of excellence in the art and craft of music.

The handcrafted awards, made from zinc alloys, are created by an artisan in Colorado to honor the achievement of the recipients.

A Glimpse into the Future

Despite its long history, zinc is a unique and modern metal. With its wide range of properties, it has few counterparts in terms of its usefulness in the constantly evolving fields of science and technology.

Its versatility has made it an essential tool for researchers pushing the boundaries in physics, chemistry, biology, and electrical engineering.

With thousands of registered patents and millions of tons of products to its name, zinc has played a pivotal role in many groundbreaking inventions of the 20th century.

From transistors to lasers, satellites to circuit boards, photocopiers to fuel cells, zinc undoubtedly stands as one of the most versatile and indispensable materials known to humankind.

———————————————————————–

Rob Putnam, ILZRO and Michael Martin, IZA

Translator: Shadi Jamili